-

Luxi Industrial Park, Luxi County, Pingxiang City, Jiangxi Province, China.

Jiangxi QOCI Electric Co., Ltd. adheres to the principle of “resource sharing, complementary advantages, sincere cooperation, mutual benefit and common development” to further strengthen school-enterprise cooperation, and actively explore and deepen new ways of “industry-university-research cooperation education” to create an educational environment that is conducive to cultivating students’ practical skills and improving their comprehensive quality. At the same time, it makes full use of school resources to serve enterprises and provide talents for enterprises.

Since its establishment in 2002, the company has gone through 19 years of ups and downs. Facing various difficulties, it has continuously pioneered and innovated, explored business models, accelerated industrial development, and achieved remarkable results in product research and development, talent training, and market development. The college student internship base was listed in QOCI Company, which injected fresh blood into the company’s talent training and technological innovation, and also put forward higher requirements for the company’s future development.

The company is a pilot demonstration enterprise for the transfer and transformation of major national science and technology projects. It has established a “industry-university-research” cooperation relationship with Nanchang University and Nanchang Hangkong University, and jointly implemented the 03 project and 5G project with Nanchang Hangkong University to create an intelligent manufacturing production line for ultra-high voltage glass insulators. It mainly promotes the intelligent development of enterprises with two major characteristic projects:

Automated production line: The production line mainly includes 6 subsystems, namely weighing and batching system, melting system, molding system, tempering system, hot and cold shock inspection system, and assembly system, realizing automated continuous operation and transportation, intelligent process control, intelligent online defect detection, ABB robot operation, and realizing intelligent automated manufacturing.

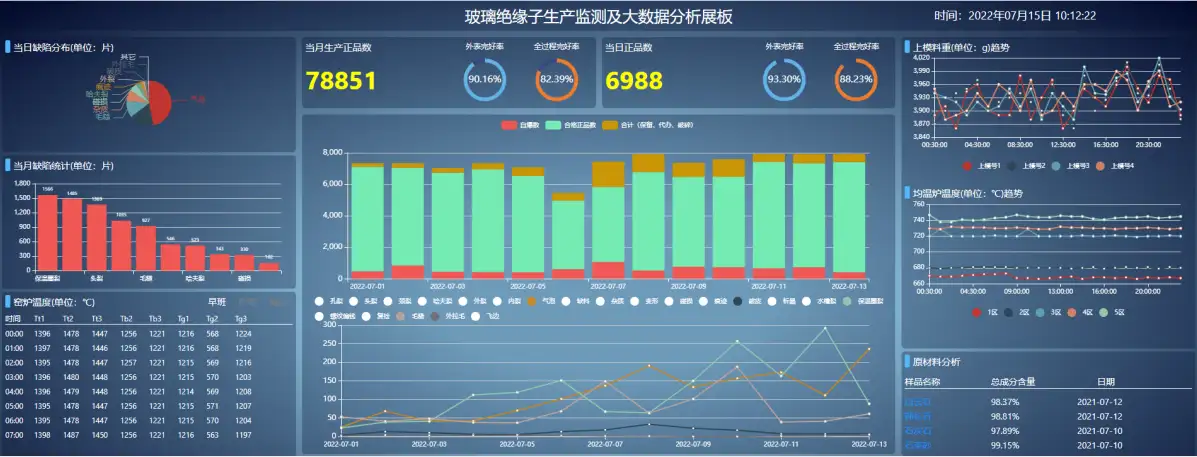

Production management platform: comprehensive real-time information collection and analysis control of the production process to realize intelligent manufacturing, automatic detection and product quality traceability of UHV glass insulators.

① Based on NB-IOT and 5G technology, a real-time collection and transmission system for production parameters in the entire process of insulator production is constructed, including adding data acquisition interface modules for existing sensors and modules for sending to factory gateways, adding data collection and communication modules such as production environment information, and designing and manufacturing factory gateways based on NB-IOT and 5G communication technologies, responsible for the interconnection between factories and data centers and user mobile terminals.

② Adopting fieldbus, Modbus, ZigBee, RFID and other technologies to build industrial control networks, realize comprehensive and in-depth perception and production system integration management and control, and build the information-physical system (Cyber-Physical Systems, CPS) of the company’s intelligent production line of UHV glass insulators. Including building an underlying perception network based on Modbus and ZigBee protocols, and connecting fixed and mobile RFID readers to ensure real-time and reliable transmission of perception and control information.

③ Build a database, receive various types of data uploaded by the factory gateway, develop mobile APPs for managers, customers and other personnel, and the data center designs the APP interface and provides data. It uses machine learning methods such as principal component analysis and deep neural networks to mine and analyze production big data, establish a relationship model between production parameters and yield rate, realize intelligent control of production equipment itself, and give decision-making suggestions for improving quality and yield rate.

④ Develop defective product detection technology based on machine vision to replace the current manual visual detection to improve detection efficiency and consistency. The main internal skills include taking a large number of pictures of good products and various defective products, and building a defective product detection model on the Keras platform based on machine learning methods such as convolutional neural network (CNN), recurrent neural network, residual neural network, and deep 11-degree neural network. Transplant the constructed detection model to the embedded platform based on RK3399Pro to achieve offline terminal fast good product detection, and at the same time, send the good product rate back to the data center.

⑤ Develop a product quality tracking system based on RFID technology. On the basis of the CPS system, build a manufacturing execution system (Manufacturing Execution System, MES) and an enterprise resource planning system (Enterprise Resource Planning, EPR) to record and manage data from the entire production process. After the semi-finished glass insulator passes the first quality inspection, an RFID tag is generated and pasted to the inside of the insulator. The raw materials, production process parameters, etc. are corresponding to the RFID tag in the database. In the subsequent process, the relevant data will be recorded based on the RFID identity to achieve product traceability.

We have effectively combined the company’s ERP system and MES system to build a transparent factory under ubiquitous perception conditions. It realizes the approval process, product inventory management, production plan management, document management, quality management, product design management, production monitoring, production scheduling management, process management, manufacturing data management, manufacturing process collection and control, product tracking, alarm management, basic data maintenance, authority management and other functions in the production process.

Through the in-depth cooperation between enterprises and universities, the company has successively passed ISO 9001:2015 quality management system, ISO 14001 environmental system, OHSAS 18001 occupational health system certification, and obtained the “Informatization and Industrialization Integration Management System Assessment Certificate” from the Ministry of Industry and Information Technology. In recent years, it has successively won honors such as “National User Satisfaction Product Enterprise”, “National High-tech Enterprise”, “Jiangxi Province Specialized and New Small and Medium Enterprises”, “Jiangxi Province Advanced Quality Management Enterprise”, “Jiangxi Province Contract-abiding and Credit-worthy Unit”, “Jiangxi Province Famous Trademark”, “Jiangxi Province Famous Brand Products”, “Jiangxi Province Green Factory”, “Jiangxi Province Green Manufacturing Demonstration Enterprise”, etc., and was selected into the “2019 Jiangxi Province 03 Special Project and 5G Project” list of the Ministry of Industry and Information Technology, the 22nd batch of provincial enterprise technology centers in Jiangxi Province, and the 2019 Jiangxi Engineering Research Center List; there are more than 20 valid patents of various types. On the basis of digesting and absorbing the mature manufacturing technology of glass insulators, the full oxygen combustion technology is used for the first time in the insulator industry to improve the melting quality of glass liquid, and the uniformity of glass liquid can reach the standard A level. At the same time, the company has the research and development capabilities of functional glass and line insulators. It has passed ISO9001 quality management system certification and ISO14001 environmental management system certification, and strictly carries out production and management in accordance with system requirements.

The company has advanced testing equipment. The testing center covers the testing of raw material composition, accessory packaging materials, semi-finished products, finished machinery and high-voltage simulation. The modern testing center ensures the quality of the company’s products. The company adheres to the concept of quality first and sustainable development, and continuously conducts research on line insulators and functional glass, enriches and innovates products, improves and expands the intrinsic quality of products, and provides better quality products for domestic and foreign power grid construction.

The company has always adhered to the corporate philosophy of “serving the society and contributing to the country”, and adhered to the development strategy of “relying on mechanism innovation to introduce high-quality talents, and relying on high-quality talents to develop new products”. It has attracted many industry technical experts from Hunan, Jiangxi, Xi’an and other places, built an excellent technical research and development team, and participated in the company’s product innovation and product standard formulation. It has successively established the Jiangxi UHV Glass Insulator Engineering Research Center and the Jiangxi High-Strength Amorphous Insulation Material Technology Center. It is a leading enterprise in the field of smart grid and smart energy products, committed to providing State Grid Corporation of China and China Southern Power Grid Corporation with UHV glass insulators and porcelain insulators for smart transmission and distribution lines, helping users improve the safety, reliability and intelligence level of electricity and energy, and improve energy efficiency and reduce carbon emissions.

The company attaches great importance to new product research and development and independent innovation, and has long adhered to the path of integration of industry, academia and research. It has had good cooperative relations with Hunan University, Nanchang University, Nanchang Hangkong University and other institutions for many years. Based on independent innovation, it also has good cooperative relations with well-known domestic industry colleagues in the field of technology.

The company’s development strategy is to actively and steadily implement a diversified development strategy based on the existing scale, fully realize the scale of the enterprise, rely on technological innovation to improve product grades, and then enhance the company’s comprehensive strength by adjusting the product structure, develop into a porcelain and electrical company of considerable scale, complete the company’s expected goals and realize the corporate brand strategy, and enhance the corporate brand value.

The company has created new momentum for intelligent manufacturing, targeted the characteristics of production and sales business, connected the data relationship of production management, inventory management, sales settlement, and sales contracts, strengthened intelligent production management, improved communication efficiency, smooth processes, improved the accuracy of business operations, and realized the strengthening of intelligent manufacturing process monitoring, enhanced the risk response capabilities of production management, strengthened the process operation of sales management, and realized production process management and refined management based on good cooperation and interaction between various business links. According to the guidance of national industrial policies and the actual situation of enterprise production development and key energy processes and equipment, the company has adopted energy-saving and emission-reduction technologies, built advanced, energy-saving, and environmentally friendly gas kilns, and used clean gas fuel to calcine electric porcelain, making full use of energy and reducing energy loss. Product energy consumption is greatly reduced, achieving the goals of energy saving and consumption reduction, waste heat utilization, emission reduction, and improving product competitiveness, and completely changing the production and operation status of traditional kilns with “three highs and one low”. At the same time, natural gas is used as fuel. Due to the high utilization rate of thermal energy, the emission of industrial pollutants is greatly reduced, which not only saves energy but also protects the environment, and truly realizes energy-saving and environmentally friendly production. The company always adheres to the business purpose of “quality first, reputation first”, based on quality, relying on science and technology, guided by the market, centered on efficiency, strictly manages and strives to create a famous brand. While providing customers with high-quality products, it also actively undertakes social responsibilities and has been widely recognized by the society.

Automated batching and kiln intelligent control system While relying on school-enterprise cooperation to improve the digitalization and information level of enterprises, it realizes intelligent optimization of production, operation, management and decision-making, reduces enterprise production costs, enhances the core competitiveness of enterprises, and plays a demonstration and leading role in promoting intelligent manufacturing in my country’s insulator industry while meeting the company’s sustainable development. In order to accelerate the improvement of the quality and reliability level of my country’s ultra-high voltage insulators, it plays a strong supporting role in the construction of ultra-high voltage projects and the development of ultra-high voltage transmission and transformation technology and equipment.